Hands-On PLC Training Courses for Industrial Automation

Master PLCs and Drive Productivity with ATS

At Adaptive Training Services (ATS), we understand the critical role Programmable Logic Controllers (PLCs) play in automating industrial processes. Partnering with Amatrol, the industry leader in industrial training solutions, we offer comprehensive PLC training programs designed to equip your workforce with the skills they need to program, troubleshoot, and maintain these essential systems effectively.

Unlock the Power of PLCs

Our PLC training program delves into the core concepts and practical applications of Programmable Logic Controllers, including:

-

PLC Fundamentals: Gain a solid understanding of PLC hardware, software, and programming languages like Ladder Logic.

-

Programming Techniques: Master the skills to write efficient and reliable PLC programs for various applications.

-

Input/Output (I/O) Systems: Learn how to configure and troubleshoot analog and digital I/O modules for data acquisition and control.

-

Troubleshooting and Diagnostics: Develop the skills to diagnose and resolve common PLC malfunctions efficiently.

-

Communication Protocols: Understand different communication protocols used for integrating PLCs with other devices and systems.

Why Choose ATS for PLC Training?

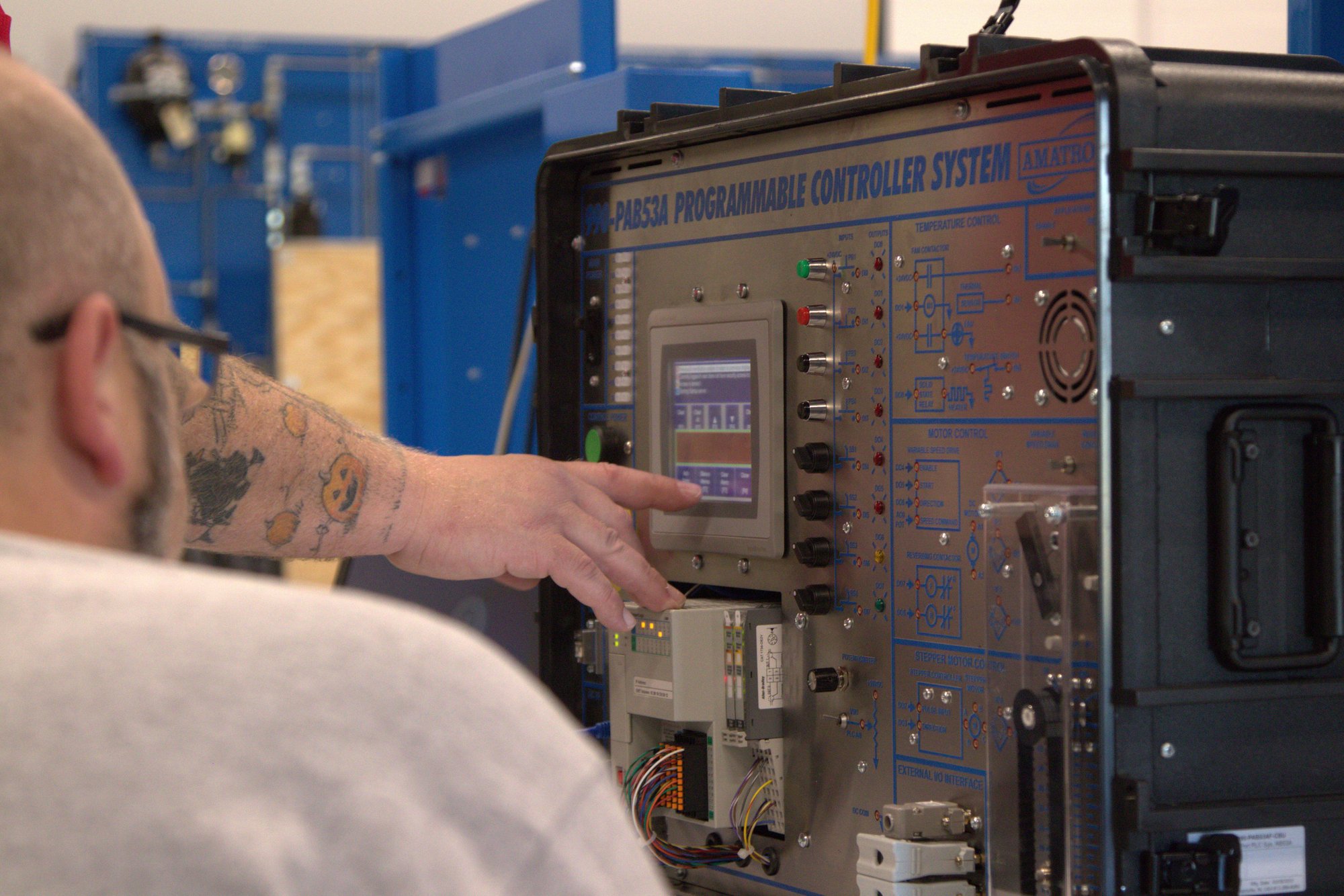

- Hands-On Learning: Our labs are equipped with state-of-the-art PLC trainers and industrial equipment, providing practical experience.

- Industry-Standard Curriculum: Our programs leverage Amatrol's renowned PLC training materials, ensuring your team acquires relevant skills for today's industrial landscape.

- Experienced Instructors: Our team of certified PLC technicians provides expert guidance, real-world insights, and troubleshooting expertise.

- Customized Training: We tailor programs to address specific PLC models and applications used in your operations.

- Flexible Delivery: Choose from on-site, online, or blended learning formats to fit your training needs.

- Measurable Results: We assess your employees' progress through hands-on exercises and practical assessments.

Empower Your Team, Drive Efficiency

Contact ATS today to learn more about our PLC training programs. We'll work with you to develop a solution that equips your workforce with the knowledge and skills necessary to program, troubleshoot, and maintain your PLC systems efficiently. Schedule a free consultation and unlock the full potential of PLCs in your operations!

Frequently Asked Questions

What is the difference between a PLC and a computer?

A PLC, or Programmable Logic Controller, is a specialized type of computer designed for industrial automation applications. While similar to a general-purpose computer, PLCs are more rugged, reliable, and specifically designed to handle real-time control of industrial processes. They are often used in harsh environments and can withstand fluctuations in temperature, humidity, and vibration.

What programming languages are used with PLCs?

The most common programming language used with PLCs is Ladder Logic, which is a graphical programming language that resembles the ladder diagrams used in relay-based control systems. However, PLCs also support other programming languages, such as Function Block Diagram (FBD), Sequential Function Chart (SFC), and Structured Text (ST).

Do I need prior PLC experience to take your training program?

No prior PLC experience is necessary to enroll in our PLC training program. Our courses are designed to cater to individuals with varying levels of knowledge. Whether you're a beginner or have some experience with PLCs, our training will provide you with the necessary skills and knowledge to succeed.