Specialized Fluid Power Training and Certification Courses

Unleash the Power of Fluid Power Training with ATS

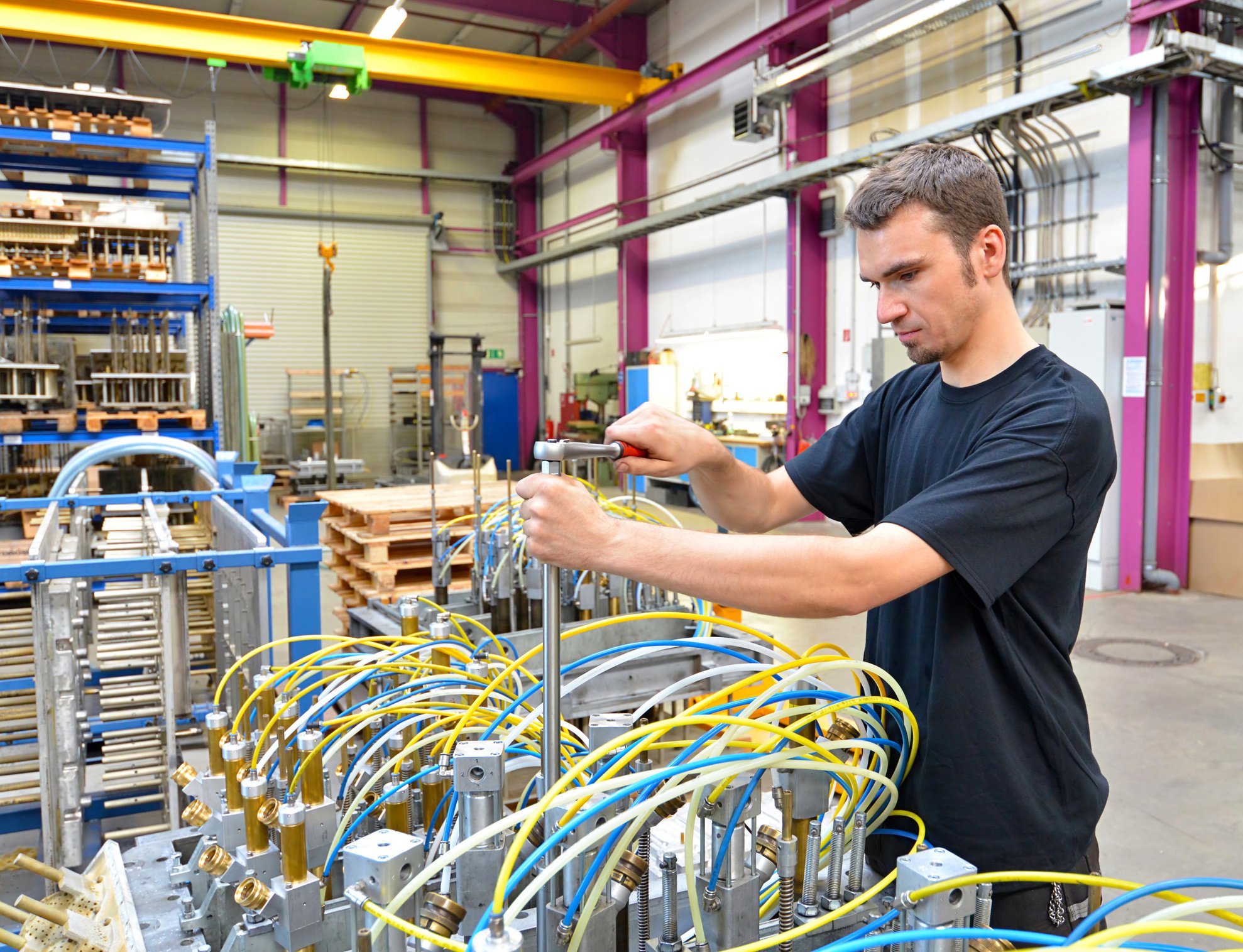

At Adaptive Training Services (ATS), we understand the versatility and power of fluid power systems in driving industrial processes. That's why we've partnered with Amatrol, the industry leader in industrial training, to offer comprehensive fluid power training programs. Our programs equip your employees with the expertise to operate, maintain, and troubleshoot hydraulic and pneumatic systems effectively.

Mastering the Fundamentals of Fluid Power

Our fluid power training program delves into the core concepts of both hydraulics and pneumatics, including:

-

Fluid Power Principles: Understand the fundamental principles governing hydraulic and pneumatic systems, including pressure, flow, and force.

-

Hydraulic Components: Gain in-depth knowledge of pumps, cylinders, valves, and other essential hydraulic components.

-

Pneumatic Components: Explore compressors, actuators, valves, and other key elements in pneumatic systems.

-

Circuit Design and Analysis: Develop the skills to design, analyze, and troubleshoot fluid power circuits.

-

Fluid Power Safety: Master critical safety practices to ensure safe operation and maintenance of fluid power systems.

Why Choose ATS for Fluid Power Training?

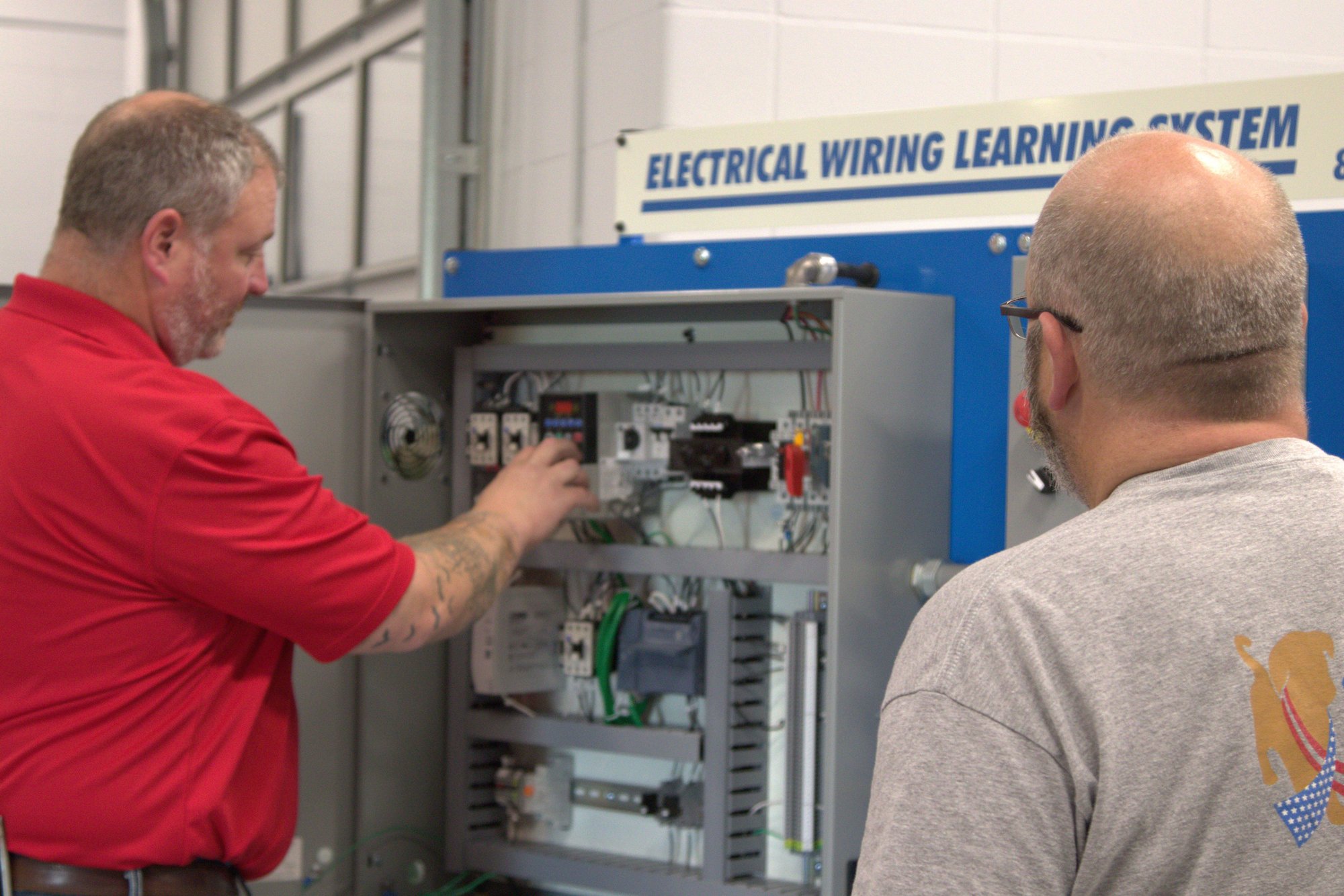

- Hands-On Learning: Our labs are equipped with industry-standard hydraulic and pneumatic training systems, providing practical experience.

- Experienced Instructors: Our team of seasoned fluid power technicians offers real-world insights and troubleshooting expertise.

- Customized Training: We tailor programs to your specific needs, focusing on the types of fluid power systems used in your operations.

- Flexible Delivery: Choose from on-site, online, or blended learning formats to fit your training requirements.

- Measurable Results: We assess your employees' progress throughout the training and provide detailed reports for tracking their skill development.

Investing in a Fluid Workforce

By equipping your team with strong fluid power skills, you'll reap several benefits:

- Increased Uptime: Well-trained personnel can identify and address potential fluid power system issues before downtime occurs.

- Enhanced Efficiency: Proper system maintenance and operation optimize performance and minimize energy consumption.

- Improved Safety: Understanding safety protocols for fluid power systems safeguards your employees and minimizes risks of accidents.

- Reduced Costs: Proactive maintenance and troubleshooting prevent costly repairs and breakdowns.

Empower Your Team, Drive Performance

Contact ATS today to discuss our fluid power training programs. We'll customize a solution that equips your workforce with the knowledge and skills to operate and maintain your fluid power systems efficiently. Schedule a free consultation and unlock the full potential of fluid power in your operations!

Frequently Asked Questions

What is the difference between hydraulics and pneumatics?

Both hydraulics and pneumatics use fluids to transmit power, but they use different types of fluids. Hydraulic systems use liquids, such as oil, while pneumatic systems use gases, such as air. Hydraulic systems are generally used for heavy-duty applications, while pneumatic systems are used for lighter-duty applications.

What is Pascal's Law and why is it important in fluid power?

Pascal's Law states that pressure applied to a confined fluid is transmitted equally in all directions. This principle is fundamental to the operation of hydraulic and pneumatic systems. It allows us to use a small force to generate a large force, which is why fluid power systems are so powerful.

What is a hydraulic accumulator and what is it used for?

A hydraulic accumulator is a device that stores energy in the form of compressed fluid. It is used to smooth out pressure fluctuations in a hydraulic system and to provide backup power in case of a power failure.